NATIONAL ASSOCIATION OF MANUFACTURERS (NAM)

Manufacturers Need a 21st-Century Infrastructure System

Great nations build and invest in great infrastructure. Too many 21st-century U.S. infrastructure systems depend on 20th-century investments. Now in an alarming state of disrepair and in urgent need of new funding, America’s infrastructure can no longer wait. Families, communities and manufacturers need modern transportation, energy, broadband and water infrastructure to meet the demands of today’s economy. The modern manufacturing economy we are building does not have the kind of infrastructure we need to support our vision for an exceptional America.

Vision and Confidence

It was the vision of our Founding Fathers to have strong ports and waterways to support trade and a postal road system to connect families and communities in a new nation. When the steam engine came along, railroads were built to link an expanding nation, and steamboats transformed freight movement on rivers and oceans, giving the United States a leading role on the global stage. Manufacturing in the United States was able to come into its own thanks to the support and growth of transportation services as well as public and private transportation networks. President Dwight Eisenhower saw the potential for the nation to be even more connected and that critical road infrastructure gaps existed, potentially hobbling America’s post-war potential.

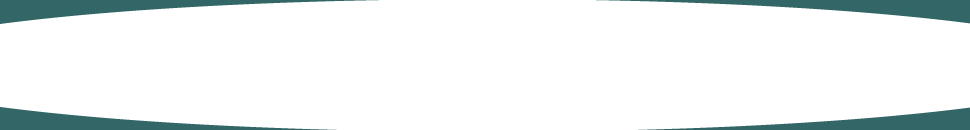

Since President Eisenhower’s vision and leadership to invest in the interstate system, U.S. infrastructure investments have been neglected. Unfortunately, NAM data demonstrates that the trend of infrastructure investment has not improved, but worsened.

Underinvestment in U.S. infrastructure worsens by the year. Infrastructure investment is only one-third of what it was in 1960.

In 2018, manufacturing optimism reached record highs as a direct result of competitive tax and regulatory policy. Tax reform and an improved regulatory environment helped to propel faster growth, with manufacturers raising wages, investing in their operations and offering innovative benefits. However, manufacturers increasingly raise concerns about rising transportation costs and insufficient infrastructure. More than 70 percent of manufacturers do not believe the state of our nation’s infrastructure is positioned to respond to the competitive needs of a growing economy.

A great nation and strong economy should not neglect the maintenance of its infrastructure or underinvest in its future. Passing a significant infrastructure bill would not only support economic growth through increased labor productivity and new job creation, but also provide confidence and vision to position manufacturers for long-term success.

Global Competitiveness

Each year, the World Economic Forum includes infrastructure as one of its key measures of economic competitiveness. For 2017–2018, the United States ranked behind many of its biggest global competitors at 9th in overall infrastructure quality.

Manufacturers and families continue to rely on outdated roads, bridges, waterways, ports, runways and drinking water and wastewater systems, many of which are more than 50 years old. Our global competitors are making strategic decisions to invest in their futures. China’s infrastructure investment is almost double the size of the infrastructure spending in the United States, and India’s infrastructure investments are growing at a rate that triples the infrastructure outlays of the United States, Canada and Mexico combined.

Manufacturers are committed to ensuring America’s infrastructure is the best in the world. It is time for the United States to take the lead again and modernize our infrastructure.

Productivity

Many manufacturers have adopted a just-in-time or lean business model to maximize efficiency. Today, companies rely on the ability to instantaneously connect with customers and suppliers, efficiently move their products to market and incorporate new technologies and innovations to reduce waste. In the end, these practices reduce costs for manufacturers, businesses and consumers alike.

Manufacturing ingenuity and productivity demand quality infrastructure. Modern infrastructure systems unleash greater productivity and support manufacturers’ gains in efficiency. But the inverse is also true—a lack of infrastructure investments stymies productivity and limits opportunities for businesses. If ports are clogged, trucks are delayed, water is shut off or access to the internet lapses, productivity and customer service are impacted. For one Indiana manufacturer, an emergency bridge closure prevented an entire production shift from getting to work, which shut down his shop floor and cost the company $1 million.

Job Creation

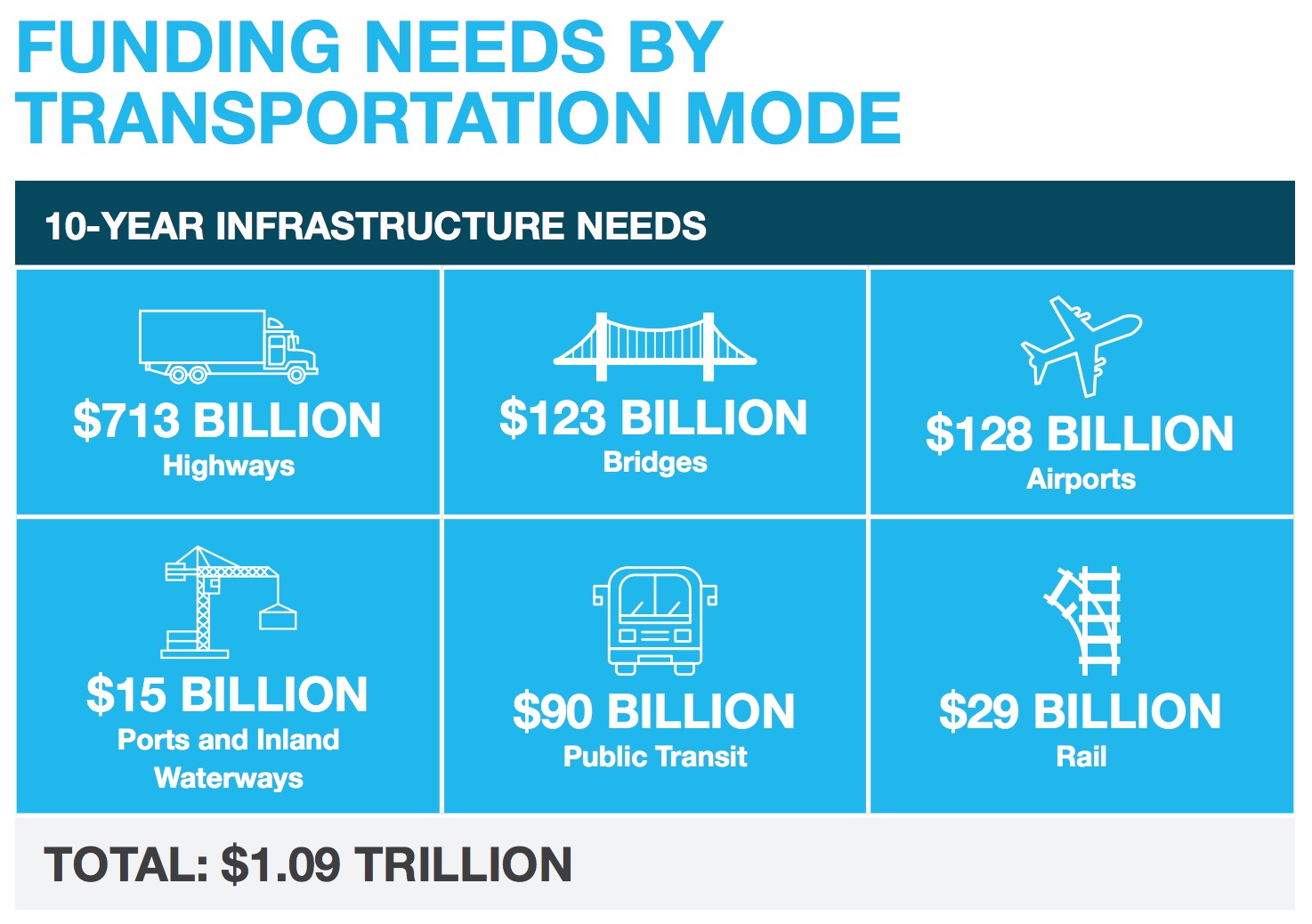

Millions of jobs are at stake when infrastructure remains deteriorating and inadequate. Without immediate action on the infrastructure crisis, the United States will lose more than 2.5 million jobs by 2025 and more than 5.8 million by 2040.

By contrast, infrastructure investments can create jobs in the near term, setting off a positive ripple effect across industries.

A 2017 PricewaterhouseCoopers report highlights that a $1 trillion infrastructure investment could create 11 million jobs. Approximately 10 percent of infrastructure jobs would be in manufacturing with specific needs for skilled workers in fields such as information technology and data science. Construction and manufacturing jobs have a powerful multiplier effect on our economy; for every $1.00 spent in manufacturing, the economy grows by $1.89.

Quality of Life

When the federal government fails to invest in infrastructure improvements, American families and businesses, in particular manufacturers, bear the brunt of the costs.

According to the American Society of Civil Engineers (ASCE), from 2016 to 2025, families will lose $3,400 every year because of deficient infrastructure. By 2026, that cost will rise to a staggering $5,100 wasted every year.

Next-generation transportation, energy, water and broadband systems will enhance the quality of life for families and communities around the country. Greater mobility and connectivity give workers better access to job opportunities and options for housing, telemedicine, shopping and recreation. In the 20th century, the proliferation of airports and international aviation agreements unlocked the wonders of convenient, low-cost, long-distance travel and opened pathways for tourism and commerce. When manufacturers are able to reduce transportation, water and energy costs through more advanced or more reliable services, consumers benefit from lower prices of household products. In short, infrastructure boosts the quality of life, from rural areas to urban centers and every community in between.

Innovation and Safety

Reducing road fatalities and injuries remains a national imperative. Human error remains the leading cause of 94 percent of all vehicle crashes. While progress has been made to address overall vehicle and behavioral safety, the advent of drones, autonomous vehicles, big data and other machine-learning applications present new opportunities and challenges to improving the nation’s traffic safety as well as our productivity.

As new technologies come online and into the heavy duty and automotive markets, vehicles are also evolving into mobile computers with wheels. This is an exciting time for automotive and truck manufacturers as well as suppliers, but to maintain a mantle of leadership, our nation’s elected officials and leaders must get safety regulations and the adoption of new technologies right. As an example, basic infrastructure, like clear lane lines and road markings, will be critical to the long-term success of autonomous vehicles. State and local investments in this area cannot be overlooked. Also, a federal regulatory approach that considers the industry a technology partner and allows for innovation will be instrumental to the further success of automated driving systems (ADS).

Physical infrastructure must also evolve to address mounting road congestion in urban and suburban areas so that new capacity can be flexible and responsive to the demands on the road in realtime. Innovation and safety are intertwined even deeper as we enter this exciting period where transportation innovations will not only transform safety but also the way we live and work.

Download full version (PDF): Building to Win

About the National Association of Manufacturers (NAM)

www.nam.org

The National Association of Manufacturers (NAM) is the largest manufacturing association in the United States, representing small and large manufacturers in every industrial sector and in all 50 states. Manufacturing employs more than 12 million men and women, contributes $2.25 trillion to the U.S. economy annually, has the largest economic impact of any major sector and accounts for more than three-quarters of all private-sector research and development in the nation. The NAM is the powerful voice of the manufacturing community and the leading advocate for a policy agenda that helps manufacturers compete in the global economy and create jobs across the United States.

RSS Feed

RSS Feed