Member Firm Ingenuity Enhancing Airport Design & Infrastructure at All Levels

- PROJECT: Nashville International Airport, Water Source Geothermal System

FIRM: Garver - PROJECT: San Francisco International Airport, Terminal 1 Interim Boarding Area B

FIRM: Syska Hennessy Group, Inc. - PROJECT: Love Field Modernization Program, Dallas, Texas

FIRM: Huitt-Zollars, Inc. - PROJECT: Los Angeles International Airport, Midfield Satellite Concourse North

FIRM: Kimley-Horn

Project: Nashville International Airport, Water Source Geothermal System

Firm: Garver, Nashville, TN

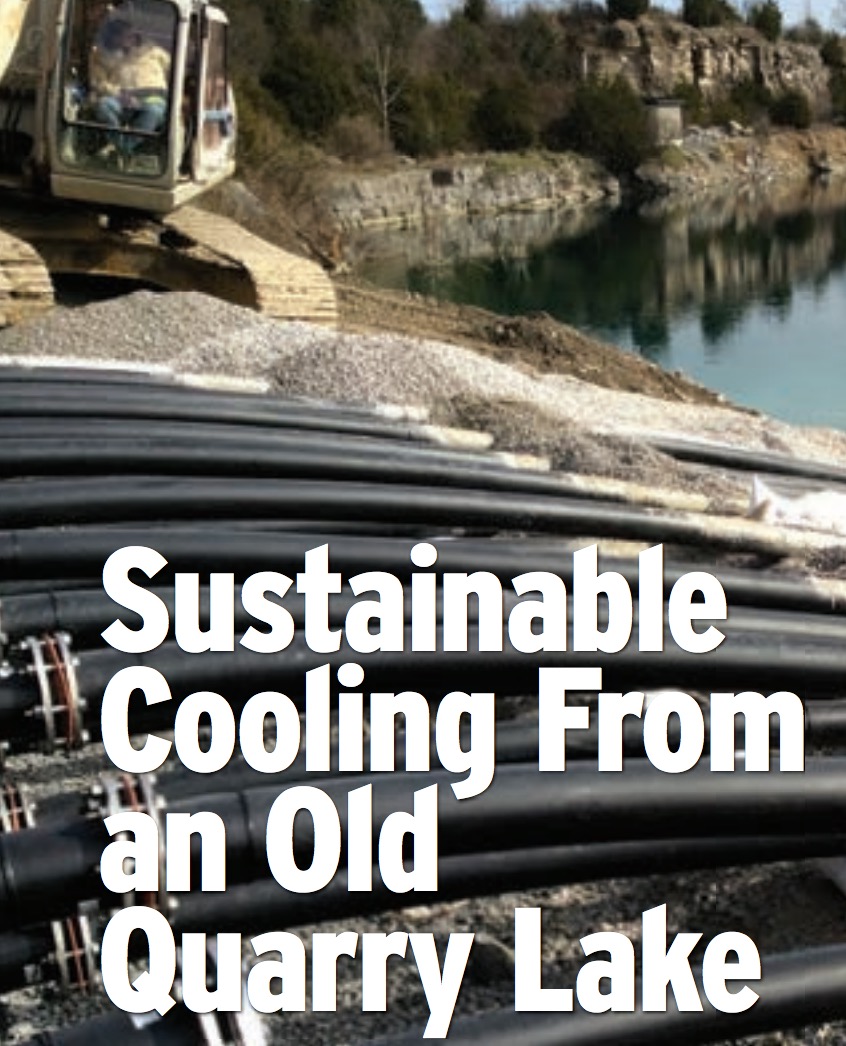

Since early 2016, a new 3,600-ton capacity geothermal system has been providing cooling for the entire terminal building at the Nashville International Airport, significantly reducing the facility’s use of both electricity and water. The nearly $10.4 million project finished three months ahead of schedule and under budget.

Since early 2016, a new 3,600-ton capacity geothermal system has been providing cooling for the entire terminal building at the Nashville International Airport, significantly reducing the facility’s use of both electricity and water. The nearly $10.4 million project finished three months ahead of schedule and under budget.

The idea to use water source geothermal cooling to replace the cooling towers in the airport’s central utility plant came out of the Metropolitan Nashville Airport Authority’s (MNAA) participation in the Sustainable Master Plan Pilot Program launched by the Federal Aviation Administration in 2010. As part of that exercise, planners considered various possible uses for the near-potable water in a 250-foot-deep lake in an abandoned quarry adjacent to the airport’s easternmost runway. They soon realized that beyond supplying water for irrigation, rental car washing and construction use, the lake’s thermal profile made it an ideal source of cooling—below the 45-foot depth, the water temperature remains at approximately 50 degrees Fahrenheit throughout the year.

“One of our team members had prior experience with this type of cooling system but on a smaller scale,” says Ryan Sisemore, vice president of Garver, which served as the civil design lead for the design-build project. “We just took the concept and ran with it.”

At the heart of the system are a dozen radiator-like lake plate assemblies submerged to a depth of 50 feet in the quarry lake. Condenser water is pumped through nearly a mile of 20-inch high-density polyethylene pipe to a manifold at the edge of the lake. From there, 6-inch pipes feed the lake plate assemblies where the condenser water is cooled by 16 degrees before returning via another manifold and pipeline to the central utility plant. The entire trip takes about 45 minutes, although that can vary because it is an on-demand system.

MNAA originally anticipated saving approximately $500,000 per year in electricity costs, but that is turning out to be a conservative estimate.

“Once you start looking at the reduction in potable water consumption, that return grows even higher,” Sisemore says. Abandoning cooling towers and using the quarry lake water for irrigation is saving MNAA 30 million gallons of potable water consumption per year.

These results are especially good in the long-term perspective. The payback period initially was expected to be about 10 years based on energy savings alone. But with a life expectancy of 50 years, this system will be functioning long after it has paid for itself.

Project: San Francisco International Airport – Terminal 1 Interim Boarding Area B

Firm: Syska Hennessy Group, Inc., San Francisco, CA

Terminal 1 is one of San Francisco International Airport’s (SFO) oldest facilities. Built in the 1960s, the terminal is now undergoing an over $4-billion multiphase redevelopment to meet modern traveler needs and enhance passenger experience.

Terminal 1 is one of San Francisco International Airport’s (SFO) oldest facilities. Built in the 1960s, the terminal is now undergoing an over $4-billion multiphase redevelopment to meet modern traveler needs and enhance passenger experience.

Syska Hennessy Group was charged with providing mechanical, electrical, architectural lighting and vertical transportation design services for the Terminal 1 Interim Boarding Area B. This $100 million project, which began in October 2014 and was completed in April 2017, involved reconfiguring the existing 18-gate terminal to a high-capacity nine-gate facility to maintain current operations over a four- to six-year period while the rest of the terminal is redeveloped.

Three critical aspects of the project were:

- Enhancing the passenger experience, even though it would be a short-term facility

- Incorporating a sustainable approach An Affordable, Sustainable Upgrade for an Interim Facility through collaboration among the entire team, again despite the short anticipated life of the facility

- Keeping costs low

In planning the terminal’s interim reconfiguration, it was not difficult to come up with life-extension type upgrades to improve the customer experience. By considering the longer term, designers also were able to take a sustainable approach. For example, much of the newly purchased major mechanical and electrical equipment may be reusable in subsequent stages of the terminal redevelopment.

“The new air handler that we installed for the rotunda expansion, where we added two gates, can be reused in another portion of the SFO redevelopment,” says Jose Herrera, principal with Syska Hennessy Group.

Large mechanical construction cost savings were achieved by upgrading, rather than replacing, existing air handling units (AHU) where possible, including filtration, fan selection and distribution. Electrostatic and carbon filters were added to both existing and new AHUs serving passenger areas to enhance indoor air quality, and all AHU supply fans were upgraded to fan-array type on variable frequency drives for increased system efficiency.

In addition to enhancing air distribution in the public areas of the terminal, such as children’s play areas and passenger waiting areas, bathroom air change rates were increased and temperature controllability was added. A pet relief room was also built with proper ventilation rates, lighting and plumbing services.

Kitchen exhaust systems for restaurants and other food concessions were improved, and cooling, ventilation and power systems for special system rooms, such as server closets, were upgraded to meet SFO requirements in redundancy, pressurization and increased capacity.

“We had to make sure the MEP infrastructure supporting Interim Boarding Area B would be maintained when we detached from the main substation to allow work to proceed on the main portion of Terminal 1,” Herrera says. “That required installing a new standby generator, but it too can be reused elsewhere in the future.”

New LED lighting was designed for architectural design alignment, even foot-candle coverage and reduced energy use. The new lighting also allows the facility to be Title 24 compliant, in terms of controllability and durability, and enhances passenger comfort to a point far beyond the typical interim facility.

Project: Love Field Modernization Program, Dallas, TX

Firm: Huitt-Zollars, Inc., Dallas, TX

Embarking upon its second century of serving North Texas, Love Field is in the final stages of a major modernization. The project team’s use of a flexible security perimeter has simplified construction access throughout the project, and new computer modeling capabilities provided the insights needed to remedy long-standing site drainage problems.

Embarking upon its second century of serving North Texas, Love Field is in the final stages of a major modernization. The project team’s use of a flexible security perimeter has simplified construction access throughout the project, and new computer modeling capabilities provided the insights needed to remedy long-standing site drainage problems.

First opened as a flying field by the U.S. Army in October 1917, Love Field converted to commercial service at the close of World War II. For the next 30 years, it was the only commercial airport in the Dallas area. But when Dallas Fort Worth International Airport opened in 1974, Love Field was relegated to a secondary role. From that point, improvements were largely limited to minor repairs to limit costs, as much of the sprawling terminal stood vacant. Even so, it remained the home of the late-1960s startup of Southwest Airlines.

In 2009, Southwest and the city of Dallas launched the Love Field Modernization Program to bring its aging infrastructure up to the level required to support flights to anywhere in the United States.

The partners set a $519 million budget to construct a new 20-gate concourse, new ticketing hall and new baggage hall; remodel the main terminal; and construct new taxiways, taxi lanes and an apron to serve the 20 gates.

Anticipating the frequently changing work area boundaries, apron designer Huitt-Zollars developed a movable Airport Operations Area (AOA) fence system built on standard K-rail traffic barriers. The portable fence enabled modification of the AOA boundary as needed so construction of the new concourse, apron and utilities always occurred outside the AOA. This radically simplified access to the construction site for workers and equipment, and minimized the mixing of construction traffic and the airlines’ ground service equipment.

“It really helped the project out in a big way,” says David Akers, vice president of Huitt-Zollars. “The K-rail not only provides a foundation for the fence, it also keeps foreign object debris from blowing onto the airfield.”

The field’s drainage problem turned out to be worse than anticipated; the system was basically undersized. “The problem with airports is that they’re large areas and fairly flat, which makes it difficult to drain,” Akers says. In 2006, a large thunderstorm underscored this problem, dumping 5 inches of rain on Love Field in a short period, causing flooding and extensive damage.

The existing drainage system–a combination of open channels, horseshoe-shaped pipes, box culverts and round pipes, with many styles of inlets and trench drains–had evolved over time.

“We developed a model of the existing system using a new nite element modeling software that allows you to analyze the pipe system plus the combination of the 3D surface terrain model on top,” Akers says. It also enabled the creation of videos that helped other project leaders visualize the problem. The undersized drainage system resulted in significant runoff moving overland across the airfield. The software generated flow arrows on the ground surface model during inundation of the design storm. These graphic indicators helped engineers develop a solution that included a new pipe network, an underground storage chamber to hold the design flow near the control tower and significant changes to the apron grading.

The new concourse opened in 2014. Improvement and expansion of parking facilities is expected to continue into 2018.

Download full article (PDF): Innovations in Airport Design

Download September/October Issue of Engineering, Inc.

About the American Council of Engineering Companies

About the American Council of Engineering Companies

www.acec.org

The American Council of Engineering Companies (ACEC) is the voice of America’s engineering industry. Council members – numbering more than 5,000 firms representing more than 500,000 employees throughout the country – are engaged in a wide range of engineering works that propel the nation’s economy, and enhance and safeguard America’s quality of life. These works allow Americans to drink clean water, enjoy a healthy life, take advantage of new technologies, and travel safely and efficiently. The Council’s mission is to contribute to America’s prosperity and welfare by advancing the business interests of member firms.

Tags: ACEC, Airport Infrastructure, airports, American Council of Engineering Companies, CA, California, Dallas, Engineering, Engineering Inc., Engineers, Garver, Huitt-Zollars, Nashville, San Francisco, Syska Hennessy Group, Tennessee, Texas, TN, TX

RSS Feed

RSS Feed